Sleepers Division

Overview

The Company manufactures concrete sleepers across its India and Africa facilities. These sleepers are used to lay new railway tracks and renovate old ones.

Among the pioneers: Among India's first concrete sleeper manufacturers with production commencing in 1982

Diversified products: Manufacture concrete sleepers for mainline, curves, bridges, level crossings, points & crossing

Capacity: Manufacturing capacity of 2 million sleepers a year across 1 facilities in India, and 1 in Namibia, Ghana and South Africa each

Experience: Manufactured more than 15 Million concrete sleepers for Indian Railways, IRCON, RITES, SAIL, NTPC, Tata Steel, DVC, etc.

Global presence: Presence in Namibia Engaged in exports to South Africa.

Segments

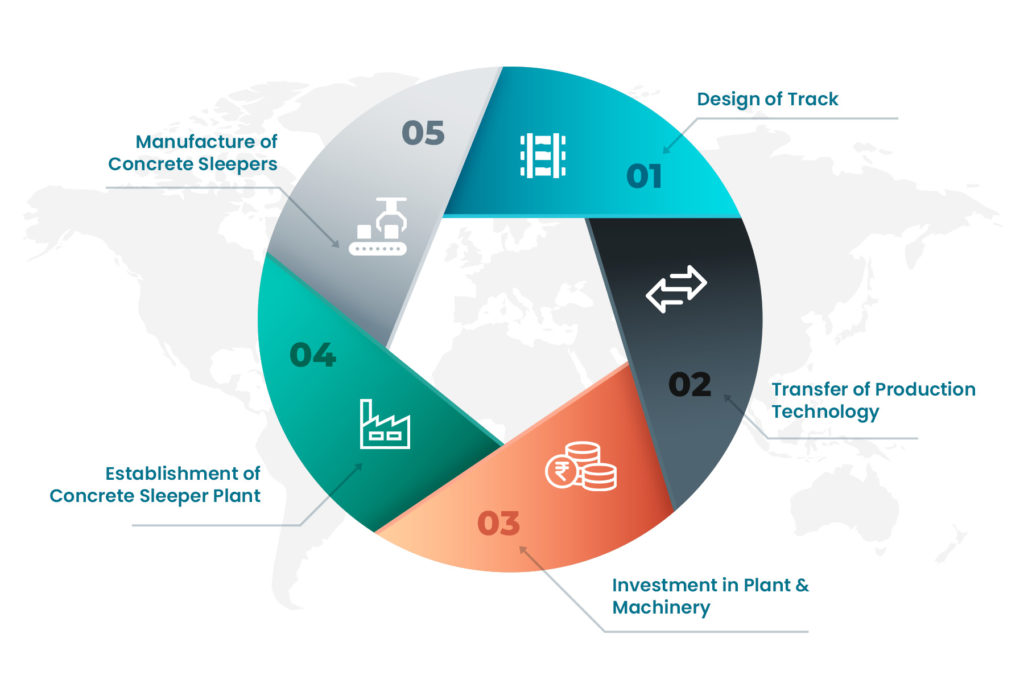

Capabilities covering entire value chain

Products

“ Our Sleeper Division, leads the industry in a host of monoblock and PSC sleepers for varied track applications. ”

We manufacture a host of monoblock and PSC sleepers for varied track applications :

- Monoblock sleepers for broad gauge (1676 mm).

- Line sleepers.

- PSC sleepers for 1 in 8.5 turnout.

- PSC sleepers for 1 in 12 turnout.

- PSC sleepers for 1 in 16 turnout.

- Bridge deck sleepers.

- Monoblock sleepers for dual gauge (1,000 mm and 1,676 mm).

- Monoblock sleepers for cape gauge (1067 mm) for 22 MT & 32 MT axle load

- Level crossing and switch expansion joint

Factories that manufacture sleepers

Our Capacities and Locations

| Factory | Capacity (units per annum) | Commissioning year | Growth driver |

|---|---|---|---|

| Panagarh, Bengal | 480,000 | 1982 | Introduction of wider base sleepers |

| South Africa | 500,000 | 2009 | Catering to requirement in the local markets |

| Namibia | 200,000 | 2010 | These markets are demonstrating strong demand |

| Ghana | 250,000 | 2023 | Helping the development of the Western Railway lines in the country |